When you hear "full size football goal", what comes to mind? For anyone who's played, coached, or even just watched a proper 11-a-side match, it's the iconic 8 feet high by 24 feet wide frame. In metric, that’s 2.44m x 7.32m.

These aren't just random numbers; they are the official dimensions mandated by the game's governing bodies, like The FA and IFAB. This standardisation is crucial because it ensures that every goal, from a local Sunday league park to Wembley Stadium, presents the exact same target. It's the bedrock of fair play.

What Defines a Full Size Football Goal

Before you consider buying a goal, it's essential to be crystal clear on what 'full size' really means. It’s not just about the width and height; it's about adhering to the official rules that keep the game consistent and fair for everyone.

Think of it like the lines on a running track. If one lane was wider than another, the race would be unfair. The same logic applies to football goals. Every keeper defending one and every striker aiming for one faces an identical challenge, no matter where they play.

The Standard Dimensions

That specific size – 8 feet high (2.44m) and 24 feet wide (7.32m) – is the universal standard for all senior 11-a-side football. It's what separates the adult game from the various youth sizes.

This isn't a new development. The core dimensions have been around for a surprisingly long time. The English Football Association first set the width at 8 yards way back in 1863. Initially, there wasn't even a crossbar! A tape was stretched across the top from 1866 to mark the 8-foot height, which was finally replaced by a solid crossbar in 1883. The fact that these measurements have stood for over 150 years speaks volumes about their importance. If you're curious, you can explore the history of football goal sizes and how they were standardised.

For easy reference, here’s a quick-reference table with the official specifications.

Official Full Size Football Goal Specifications (FA & IFAB)

This table breaks down the mandatory dimensions for a regulation full size football goal, as set by governing bodies.

| Specification | Measurement (Imperial) | Measurement (Metric) | Notes |

|---|---|---|---|

| Height (Internal) | 8 feet | 2.44 metres | Measured from the ground to the underside of the crossbar. |

| Width (Internal) | 24 feet | 7.32 metres | Measured between the inside of each goalpost. |

| Crossbar & Posts | Max 5 inches | Max 12 centimetres | Must be of equal width and depth, typically square or round. |

These are the non-negotiables. Any goal used for an official senior 11-a-side match must meet these exact measurements.

Key Types of Full Size Goals

While the dimensions are fixed, the construction and installation of goals can vary significantly. Each type has its own pros and cons, depending on the pitch, frequency of use, and budget. Understanding these categories is the first step to choosing the right equipment.

- Fixed Goals: Often called socketed goals, these are the most permanent and stable option, installed deep into the ground with concrete-filled sockets. They are perfect for dedicated pitches.

- Freestanding Goals: These goals sit on the pitch surface and are not permanently fixed. This makes them movable, but it's crucial they are properly anchored with counterweights to prevent tipping and ensure player safety.

- Portable Goals: Much lighter and often designed for quick assembly and disassembly, these are ideal for training sessions, multi-use pitches, or anywhere a temporary setup is needed.

The uniformity of a full size goal ensures that a shot that finds the top corner in a Sunday league match is just as impressive as one scored at Wembley. It's the standard that connects every level of the beautiful game.

Choosing the Right Goal Material and Type

Selecting a full-size football goal is a significant decision for any club, school, or organisation. The choice primarily comes down to two factors: what the frame is made of and how it’s installed. Getting these right ensures you have a goal that is durable, safe, and provides long-term value.

Get it wrong, and you could end up with something that doesn't fit your pitch, rusts within a season, or worse, becomes a safety hazard. Let’s break down the options so you can make a smart investment that will see you through countless matches.

The Great Material Debate: Steel vs. Aluminium

The material of the frame is the core of your goal. In the UK, the two main options are steel and aluminium, each with distinct advantages.

Think of steel goals as the traditional, no-nonsense centre-back. They are incredibly tough, robust, and can withstand heavy use from players and exposure to the weather. However, this strength comes with significant weight, making them difficult to move. They are also prone to rust if the protective paint or coating gets chipped.

On the other hand, aluminium goals are like modern, versatile wing-backs. They are much lighter, which is a huge advantage for training grounds or multi-use pitches where you need to move them. Crucially, aluminium does not rust. It will stand up to the British rain season after season without corroding.

While steel offers brute strength, aluminium's lighter weight and rust-proof nature often make it the more practical choice for clubs needing flexibility and long-term durability with less maintenance.

To make the choice clearer, let's compare them side-by-side.

Steel vs Aluminium Football Goals: A Comparison

This table breaks down the key differences to help you decide which material is the right fit for your pitch and budget.

| Feature | Steel Goals | Aluminium Goals |

|---|---|---|

| Durability | Extremely high, very robust and resistant to impact. | Very durable, though slightly less rigid than steel. |

| Weight | Very heavy, making them difficult to move once assembled. | Lightweight and easy to move, ideal for portable models. |

| Weather Resistance | Prone to rusting if paint or galvanised coating chips. | Naturally rust-proof, offering excellent long-term weather resistance. |

| Cost | Generally less expensive upfront for basic models. | Often a higher initial investment, but can be more cost-effective over time. |

| Best For | Permanent, fixed installations at dedicated football grounds. | Multi-use pitches, training grounds, and portable setups. |

Ultimately, if you're setting up a permanent pitch and the goals will never move, steel is a solid, budget-friendly option. For most other situations, the practicality and longevity of aluminium are hard to beat.

Fixed, Freestanding, or Portable Goals?

Once you’ve settled on a material, you need to decide how the goals will be installed. This choice depends entirely on your pitch and its usage.

- Fixed (Socketed) Goals: These are the most permanent and stable option. The posts slide into deep sockets that are concreted into the ground, making them ideal for professional stadiums and top-level clubs where the pitch is dedicated solely to football.

- Freestanding Goals: These offer a great mix of stability and flexibility. They sit on top of the ground and must be securely anchored with weights or ground pins to prevent tipping. They are perfect for 3G/4G pitches where digging is not possible, or for grass pitches used for multiple sports.

- Portable Goals: Built for convenience, these are the lightest and easiest to set up and take down. They are the go-to choice for training drills, small-sided games, or a proper kickabout in the park.

Navigating Critical Safety Standards

A full size football goal is a heavy piece of equipment that demands respect. Ensuring it is completely safe isn't just a good idea—it’s a fundamental responsibility for any club, school, or organisation in charge of a pitch.

Ignoring safety standards is a major liability. An unanchored freestanding goal can be extremely dangerous. For the safety of players and the public, understanding and adhering to UK safety standards is non-negotiable.

Understanding BS EN 748

The most important standard you need to know in the UK is BS EN 748. This is your guarantee that the goal has been rigorously tested for stability and strength.

When you buy a full size football goal certified to this standard, you know it’s built to withstand the force of a competitive match without risk of tipping over or structural failure. It is the official benchmark for all senior 11-a-side goals used in competitive games.

Think of the BS EN 748 certification as a safety MOT for your goal. It confirms the equipment is fit for purpose, structurally sound, and meets the strict requirements needed to keep players safe.

Checking for this certification should be your first step. It’s the clearest indication that the manufacturer has prioritised safety, giving you genuine peace of mind.

Key Safety Checks Before You Buy

Beyond official certification, there are a few practical things you should always check. These details directly impact the stability and security of your full size football goals.

-

Anchoring Systems: For any freestanding goal, the anchoring system is vital. Ensure the goal comes with the correct anchors for your pitch—whether that's grass, astroturf, or an indoor surface. Never use a freestanding goal without its counterweights or anchors properly secured.

-

Structural Integrity: Examine the quality of the welds and joints. A well-made goal will have clean, strong welds with no signs of cracking or weakness. The frame should feel solid and sturdy, without any wobbling or flexing at connection points.

-

Manufacturer Reputation: Always purchase from a trusted supplier. Established brands are more likely to adhere to strict safety regulations and provide clear instructions for assembly and anchoring. For example, the range of full size football goals at SoccerWares is selected with these safety benchmarks as a priority.

Ultimately, the responsibility for player safety falls on the club or school. Ensuring your equipment is fully compliant with standards like BS EN 748 isn't just about ticking a box; it's about protecting your players, staff, and organisation from serious accidents.

Your Step-by-Step Installation Guide

Buying a top-quality goal is only half the job. How you install it is just as important. A poorly assembled or anchored goal is not only a performance issue—it's a serious safety risk. This is our practical, no-nonsense guide to setting up your full size football goals securely, whether you've chosen socketed or freestanding models.

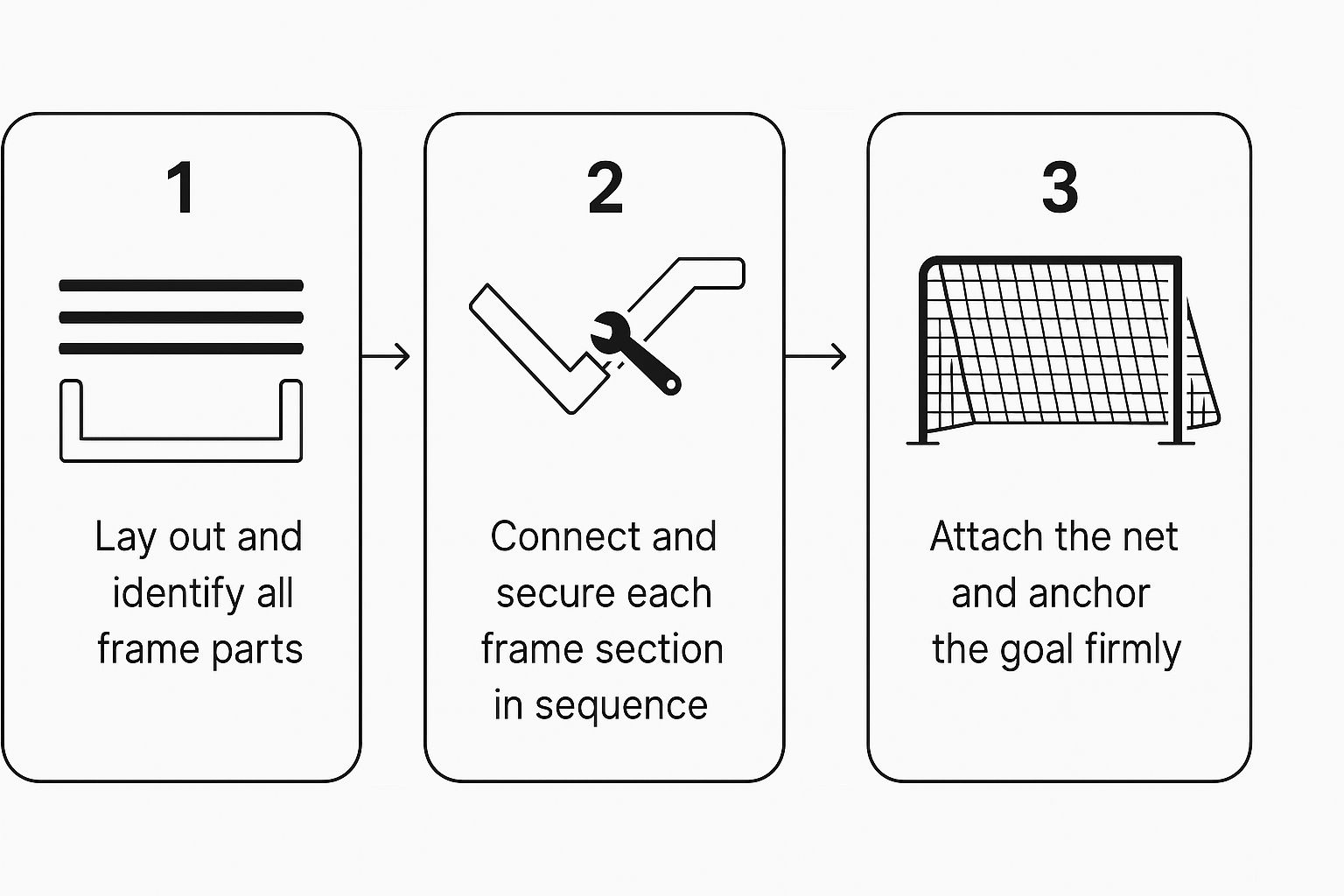

This simple infographic breaks down the core assembly process that most full size football goals follow.

As you can see, it’s a logical flow from building the frame to the final anchoring. That last step—anchoring—is the one you absolutely cannot afford to get wrong.

Installing Socketed Goals

Socketed goals are the gold standard for stability, but that stability comes from getting the groundwork right. Rushing this stage can lead to leaning goalposts and significant problems later on.

Before digging, get your tools ready. You’ll typically need a tape measure, a spirit level, a post-hole digger (or spade), and ready-mix concrete.

Step-by-Step Process for Socketed Goals:

- Measure and Mark: Use your tape measure to precisely mark where your ground sockets will go. The distance between the centres of the two sockets must be exactly 24 feet (7.32 metres).

- Dig the Holes: Excavate the holes for the ground sockets. A typical hole is around 60cm x 60cm x 60cm, but always double-check the manufacturer’s instructions, as specifications can vary.

- Set the Sockets: Place the sockets into the holes. Use your spirit level to ensure they are perfectly upright and aligned. This is a crucial step—if the sockets are crooked, the goals will be too.

- Pour the Concrete: Mix and pour the concrete, filling the holes. Continually check that the sockets haven’t shifted, ensuring they remain perfectly level.

- Let It Cure: Allow the concrete to cure completely according to the instructions, which usually means waiting at least 72 hours. Once it's fully hardened, you can slot the goalposts into the sockets.

The biggest mistake people make is putting the posts in before the concrete has fully cured. The foundation is everything for the long-term safety and stability of your goal.

Assembling and Anchoring Freestanding Goals

Freestanding goals offer great flexibility, but their safety is entirely dependent on proper assembly and anchoring. Never skip the anchoring step, regardless of the playing surface.

The tools needed are usually simple: a mallet, any Allen keys or spanners included, and a tape measure.

Correct Assembly and Anchoring:

- Lay Out All Parts: Unpack everything and check all components against the parts list. This will save you frustration later if you discover something is missing.

- Assemble the Frame: Follow the manufacturer's guide to connect the posts, crossbar, and backbars. Ensure all bolts are tight and secure, but avoid over-tightening as this can damage the frame.

- Attach the Net: With the frame built, attach the net using the clips or ties provided. Start from the top corners and work your way around for an even fit without sagging.

- Anchor Securely: This is the most critical step. Use the specific anchors or counterweights designed for your goal and the surface you’re on. This might mean U-pegs for grass or heavy counterweights for artificial turf. The goal must be completely stable and impossible to tip forward.

Correct installation means your goals will be match-day ready and safe for every player. Taking the time to do it properly is an investment that always pays off.

If you're looking for goals that come with clear, easy-to-follow guides, explore the full size football goals available at SoccerWares.

A Simple Goal Maintenance Checklist

Full size football goals are a major investment for any club, and like any valuable asset, they need regular care to stay safe and durable. Maintenance isn't just about appearance; it’s about protecting your players and maximising the lifespan of your equipment.

Think of it as a quick MOT for your goals. A simple, repeatable checklist helps you catch small problems—a fraying net, a loose bolt—before they turn into expensive repairs or a safety hazard. This proactive approach ensures your goals are always secure and ready for match day.

Pre-Match Checks for Groundstaff

A quick inspection before every match can make all the difference. These checks take only a few minutes but are vital for player safety.

- Net Inspection: Walk around the net, looking for any holes, rips, or frayed sections. A ball passing through a hole can cause confusion, and a small tear can quickly worsen.

- Frame and Fixtures: Check that all bolts, nuts, and fixtures are properly tightened. Give the crossbar and posts a firm push to ensure there is no wobbling or unexpected movement.

- Anchoring Security: For freestanding goals, confirm that all anchors or counterweights are correctly and securely in place. They should not be loose or easy to shift. This is the most important pre-match safety check.

Seasonal Maintenance Tasks

Beyond pre-match checks, setting aside time for a deeper clean and inspection at the start and end of each season will significantly extend the life of your full size football goals. This is when you can address long-term wear and tear.

A well-maintained goal is a safe goal. Just a few minutes of care each week can prevent the kind of structural failure that leads to accidents, ensuring your pitch remains a safe place to play.

A more thorough seasonal plan will keep your equipment in top condition.

Your End-of-Season Checklist:

- Give Them a Proper Clean: Use a mild detergent and water to wash down the entire frame. This removes mud and grime that can damage paintwork and cause rust on steel goals.

- Inspect for Damage: Once clean, closely examine the frame for any deep scratches, dents, or signs of corrosion. Pay special attention to welded joints to ensure there are no cracks.

- Clear Out the Sockets: For socketed goals, remove the posts and clear any debris, soil, or water from the ground sockets. This prevents damage and ensures a snug fit next season.

- Store Them Properly: If your goals are portable or freestanding, store them in a dry, secure location during the off-season. This protects them from harsh weather and prevents UV damage to the nets.

To make the job easier, consider using products designed for goal care. You can find a range of goal maintenance accessories at SoccerWares to keep your gear in pristine condition.

Why High-Quality Goal Nets Matter

The goal frame provides the structure, but the net gives a goal its character. A top-quality net does more than just stop the ball; it provides the satisfying confirmation of a goal, withstands powerful shots, and endures the British weather. It’s not an accessory—it's an essential component.

The net’s importance is rooted in the game's history. Before nets, matches were filled with disputes over whether the ball had actually crossed the line. In 1891, Liverpool engineer John Brodie invented the goal net, a simple solution that professionalised the sport by providing clear, visual proof of a goal.

Choosing the Right Net for Your Needs

Not all nets are the same. The right choice depends on the level of play and the amount of use it will endure.

A few key factors determine a net's quality and resilience:

- Twine Thickness: This is the best indicator of durability, measured in millimetres (mm). A standard net for training might be 2-2.5mm, but for competitive full size football goals, you should look for heavy-duty 4-5mm nets designed to absorb the power of high-velocity shots.

- Material: Most modern nets are made from high-density polypropylene (HDPE). This material is ideal as it’s rot-proof, UV-stabilised to prevent sun damage, and doesn't absorb water, avoiding heavy, sagging nets in the rain.

- Knot Type: Nets can be either knotted or knotless. Knotted nets are traditionally considered stronger at the joints, making them a popular choice for senior football where shots have significant force.

Choosing the right net is a balance between budget and performance. Investing in a thicker, high-grade polypropylene net may cost more initially, but it will outlast cheaper alternatives, saving you money and hassle season after season.

Installation and Care Tips

Correct installation makes a huge difference. A sagging or overly tight net not only looks unprofessional but is also more prone to damage. Always use the provided clips or ties, starting from the top corners and working around the frame to achieve even tension.

For a more detailed walkthrough, feel free to check out our dedicated guide on choosing the perfect football goal nets.

Regular care also goes a long way. After matches, check the nets for small rips or tears, which can often be repaired before they worsen. If possible, take the nets down during the off-season and store them in a dry place away from direct sunlight to extend their lifespan significantly.

Got Questions? We’ve Got Answers

Thinking about buying a full-size goal? We get asked many of the same questions by clubs and groundskeepers, so we've gathered them here to provide clarity.

Here are the answers to the most common queries we receive.

How Much Space Do I Need Behind a Full Size Goal?

For safety, a clear run-off area of at least 3 to 5 metres behind the goal line is recommended.

This space is non-negotiable. It allows players to slow down safely after shooting and ensures the net can hang freely without catching on fences or walls. Always check your specific league's rulebook, as some may have stricter requirements.

Are Freestanding Goals Safe for Competitive Matches?

Yes, provided they meet British Safety Standards like BS EN 748 and are correctly anchored for the playing surface.

Their safety depends entirely on how they are secured. Whether you're using ground anchors or counterweights specified by the manufacturer, they must be used every single time. An unanchored freestanding goal is a serious hazard and should never be used.

The stability of a freestanding goal isn't in the goal itself, but in the anchoring system that holds it down. Without proper anchoring, it's just a heavy, unstable frame.

Can I Leave Portable Goals Outside All Year?

While high-quality aluminium and treated steel goals are built to withstand the British weather, it’s always best practice to store them indoors during the off-season if possible.

Storing them in a dry area protects the frame from the worst of winter frost and prevents the sun from causing unnecessary UV damage to the net. It’s a simple step that can significantly extend the life of your equipment.

What Is the Difference Between Socketed and Freestanding Goals?

The key difference is permanence versus portability.

Socketed goals are the most stable option as they are fixed into sleeves (sockets) concreted deep into the ground. Once installed, they are not intended to be moved, making them perfect for permanent, dedicated pitches.

Freestanding goals are designed to be moved. They sit on top of the playing surface and rely on anchors or heavy counterweights for safety. They are the ideal solution for multi-use grounds where the pitch layout needs to be flexible.

At SoccerWares, we provide a curated selection of goals and training equipment designed for performance and safety. Explore our collection at soccerwares.com to find the perfect gear for your club or training ground.